Product Series

News

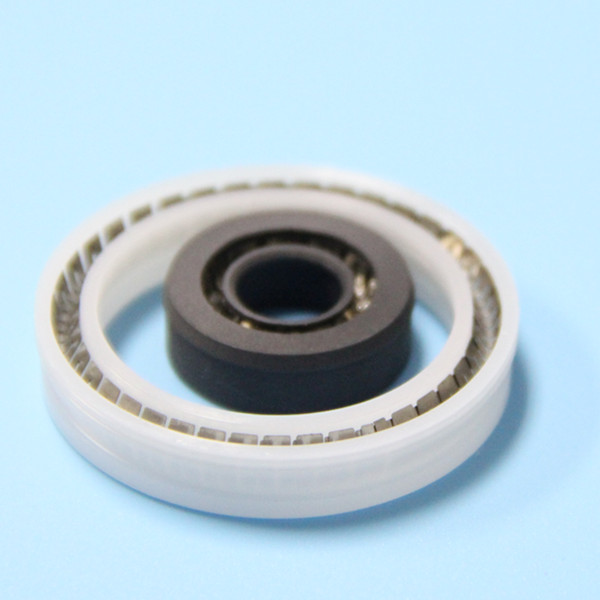

Spring energized seals Characteristics and Applications.

Update:2016-10-26

Spring energized seals is a high performance seal, it is a U shape in PTFE material with special spring, with PTFE excellent physical and chemical properties, so as to maintain the desired sealing performance.

Let’s learn about the Spring energized seals characteristics and applications.

Characteristics.

1. Effectively reduce wear and friction.

2. Dimensional accuracy.

3. Compact structure, can be installed in the standard O-ring groove, greatly increase sealing capacity and service life.

4. The seals material is PTFE, it is clean, and will not pollute the process, low friction coefficient.

5. Made by CNC machine, without tooling fee, particularly suitable for a small variety of seals.

6. Spring energized seals can fully meet increasingly and diversity harsh industrial needs.

Application.

Vacuum pump.

Loading and unloading arm rotary joint.

Valve.

Beverage, water, beer filling equipment.

Automotive, aerospace.

Etc.

Working condition.

Pressure, 40 MPa

Temperature, —40~—260℃

Speed, 2m/s

Medium, virtually all fluids chemicals and gases.

DSH Seals is a professional manufacturer of Spring energized seals,carbon filled PTFE spring energized seals, Ekonol filled PTFE spring energized seals, Polyimide filled PTFE spring energized seals, Virgin PTFE spring energized seals, UHMWPE spring energized seals.