Product Series

News

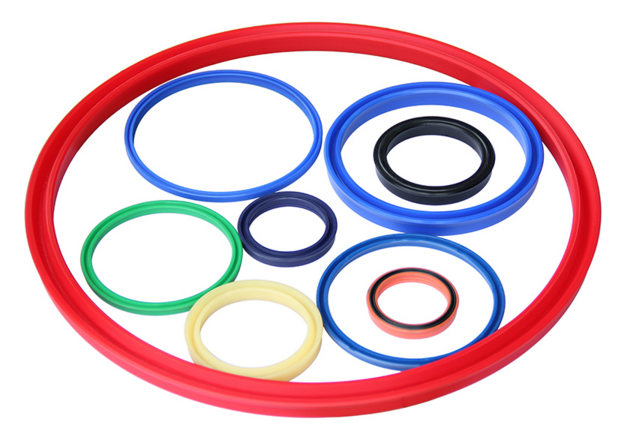

Hydraulic seals—Wiper seals

Update:2018-09-20

In hydraulic seals, oil seals can be used as wiper seals, but when the dust is serious or to protect other seals, it often used specialized wiper seals.

Wiper seals in the hydraulic seals used rubber seals, felt (square wiper seals or step wiper seals) are used more in air pressure machinery. The hydraulic cylinders for aircraft and cold working environment use metal dust seals to deal with the external icing of the piston rod. The chemical department also uses metal dust seals to prevent sticking on the piston rod.

Square compact wiper seals or step compact wiper seals belong to filler seals in the sealing mechanism. Wiper capability is related to tightness of contact. The contact is tight, the wiper capability is better, but friction resistance is big. Actually wedge scrapers have no difference with lip seals.

It scrape away dust and dirt depending on the contact force of lip tip, the friction resistance is small. Sealing and wear have big influence on the surface angel of lip tip and shaft, affect wiper capability. When the lip tip outward, it will get satisfying effect only the angel is more than 4°. When the lip tip inward, wiper effect is not good.

The surface contact of lip and shaft also directly affect wiper effect and wear of lip. There are some common contact situations. Normal contact status, thin oil film, good wiper effect, less wear;

The interference is too large, the contact is too tight, and the contact surface is wide, changing the contact angle, causing the lip tip to lift up, not only the dust-proof effect is bad, but also the frictional resistance is large,

the lip tip contact is insufficient, the friction is not large, but it cannot dust-proof; The contact angle of lip tip is too large, dust-proof effect is instant, easy to wear, becoming the reason of serious oil leakage.

In hydraulic seals, wiper seals are very important to protect critical part of hydraulic equipment. Infiltration into the dust not only wears the seal, but also greatly wears the guide ring and the piston rod. Impurities enter the hydraulic medium and also affect the function of the operating valve and pump.

In the worst case, these devices may also be damaged. The dust ring removes any dirt from the surface of the piston rod but does not damage the oil film on the piston rod, which is also beneficial for the lubrication of the seal.