Product Series

News

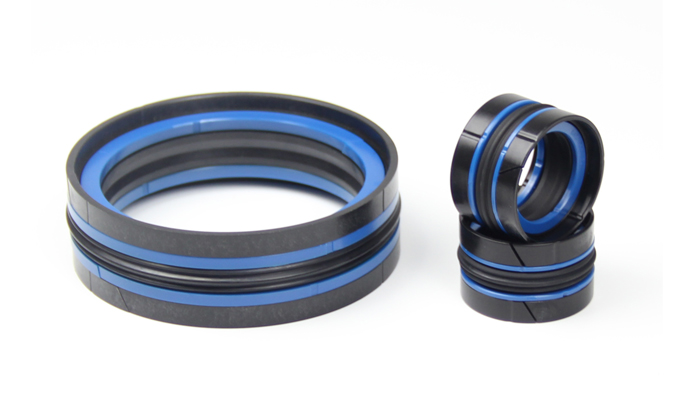

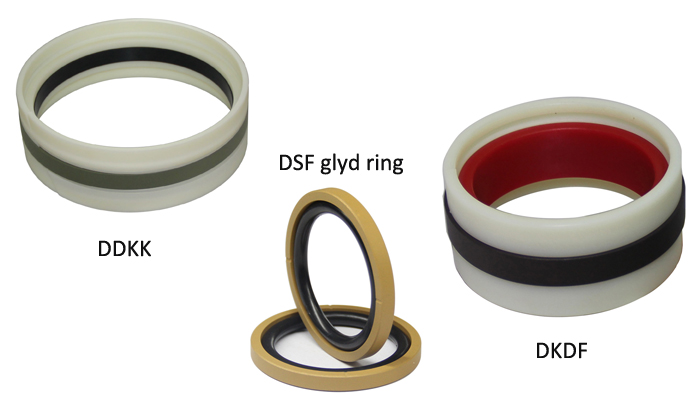

Compact seals

Update:2018-10-13

1. Sealing materials

(1) Meet the required sealing performance in physical;

(2) During the period of use, maintain the physical performance;

(3) Wear resistance. Rubber and synthetic rubber are ideal sealing materials. The sealing materials currently used are mainly made of synthetic rubber or leather. Synthetic rubber has low rigidity and can be deformed with unevenness of sealing surface; high tensile strength and elongation, high impact.

2. Selection of seals structure

According to different working pressure, can choose the structural form of the seal. But any seal material cannot meet multiple performance requirements at the same time. A seal with a certain elasticity. The sealing component type PTFE is used as a sealing material for the sliding surface, and an elastic force is applied from the back with an O-ring.

3. Geometry and size of seals

The material of the seal works for a long time at the operating temperature and increases the volume by about 10-20%. The design of the size of the stuffing box for the V-ring must take into account the volume expansion factor of the seal during operation. Otherwise it will cause adhesion of the seal, resulting in excessive friction and damage.

The clearance of the O-ring is strictly controlled to prevent crowding. The geometry and size of the seal itself have a great influence on the sealing and friction performance of the seal itself, and should have reasonable design according to different working conditions.

4. Improve the surface finish of seals

Increasing the sealing surface finish can reduce the coefficient of friction and improve the friction conditions. The sealing surface acting on the linear motion needs to be honed; the rotating surface of the sealing surface needs to be ground and polished.

5. Correct installation of seals

The seal is often damaged before it is worked due to improper assembly. The sealing ring must be chamfered to avoid scratching the seal sharply or as a guide when installing seals. When installing the seal to be threaded, a special installation tool must be used to protect the seal from scratching when the sealing surface is not installed.