Product Series

DUR

- Code:DUR

- Pressure≤(MPa):40

- Speed≤(m/s):0.5

- Temp.Range℃:-30/+80

- Material:PU

- Medium:Mineral oil based hydraulic fluids, barely flammable hydraulic fluids, water,air and others.

- Application:Mobile hydraulics, Standard cylinders, Machine tools Presses

| Application Range | |||||||

| TYPE | DWG |

Pressure (MPa) |

Temperature(℃) | Sliding speed (m/s) |

Features |

Medium |

Standard or can fit the groove |

| DUI |

|

40 | -30…+80 | 0.5 |

Standard design,with shortened inner lip,can absorb defflections |

Mineral oil based hydraulic fluids, barely flammable hydraulic fluids, water,air and others. |

GB/T10708.1 RU0 IDI |

| DUR |

|

40 | -30…+80 | 0.5 |

Heavy duty,two sealing lips and back up ring |

ISO 5597/1 RU3 |

|

| DUC |

|

40 | -30…+80 | 0.5 |

Heavy duty,two sealing lips and back up ring |

ISO 5597/1 RU3B |

|

| DUA |

|

40 | -30…+80 | 0.5 |

Design for small groove |

ISO 5597/1 RU1 ISI |

|

| DUZ |

|

40 | -30…+80 | 0.5 |

Design for small groove, two sealing lips |

ISO 5597/1 RU2 |

|

| DUB |

|

50 | -30…+80 | 0.5 |

Design for small groove,two sealing lips with back up ring |

ISO 5597/1 RU2B |

|

| DUL |

|

40 | -30…+80 | 0.5 |

Has hydrodynamic back-pumping ability |

ISO 5597/1 RLS/RLM | |

| DUS |

|

25 | -30…+80 | 0.5 |

Can fit in the same DSJ@DSH housings,which is ISO standard,mainly as a secondary seal,see DSJ@DSH for groove size |

ISO 7425/2 GB/T15242.3 RU6 |

|

| Material | |

| Seal | Back-UP Ring |

| PU | POM/PTFE/PA |

| Pressure | 160bar | 250bar | 400bar |

| Max Gap E | E≤0.6mm | E≤0.4mm | E≤0.3mm |

Order Example for standard version:

Rod Diameter d=100mm

Groove Diameter D=120mm

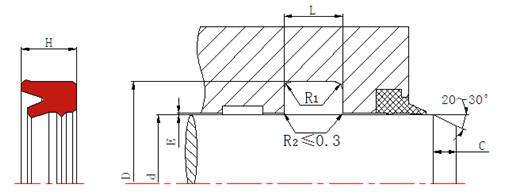

Seal Width H=12mm Type DUR

Order Code: DUR 100*120*12

Installation Dimension table based on Metric Size

| d h9 | D H10 | L+0.2 | H | C≥ |

| 20~50 | d+8 | 6.3 | 5.7 | 3 |

| 20~50 | d+10 | 6.3 | 5.7 | 3.5 |

| 20~100 | d+8 | 7 | 6 | 3 |

| 20~150 | d+8 | 7.5 | 6.5 | 3 |

| 20~150 | d+10 | 7.5 | 6.5 | 3.5 |

| 20~100 | d+10 | 8 | 7.2 | 3 |

| 20~150 | d+10 | 8 | 7.2 | 3.5 |

| 20~150 | d+8 | 8.5 | 7.5 | 3 |

| 20~150 | d+10 | 8.5 | 7.5 | 3.5 |

| 20~200 | d+8 | 9 | 8 | 3 |

| 20~50 | d+10 | 9 | 8 | 3.5 |

| 20~100 | d+8 | 10 | 9 | 3 |

| 20~100 | d+10 | 10 | 9 | 3.5 |

| 20~100 | d13 | 10.5 | 9.5 | 5 |

| 20~200 | d+10 | 11 | 10 | 3.5 |

| 20~150 | d+15 | 11 | 10 | 5 |

| 20~200 | d+8 | 12.5 | 11.5 | 3 |

| 20~200 | d+10 | 12.5 | 11.5 | 3.5 |

| 20~200 | d+15 | 12.5 | 11.5 | 5 |

| 20~200 | d+10 | 13 | 12 | 3.5 |

| 50~200 | d+15 | 13 | 12 | 5 |

| 20~250 | d+20 | 13 | 12 | 6.5 |

| 20~150 | d+20 | 14.5 | 13.5 | 6.5 |

| 50~200 | d+10 | 15 | 14.3 | 3.5 |

| 50~250 | d+20 | 16 | 15 | 6.5 |

| 100~300 | d+25 | 16 | 15 | 7 |

| 100~300 | d+30 | 19 | 18 | 7 |

| 100~300 | d+25 | 20 | 19 | 7 |