Product Series

News

Seven Industries

Update:2018-08-22

First, engineering machinery seal / parts / repair kit (piston compact seal SPGO)

Engineering machinery is an important part of the equipment industry. In generally, the mechanical equipment necessary for the construction of earth and stone works, pavement construction and maintenance, mobile lifting and unloading operations and various mechanical construction projects required for various construction projects is called construction machinery.

The seal repair kit generally refers to the sum of all seals and associated consumables at a particular location on a mechanical device. In most mechanical equipment, rubber, plastic or other non-metallic seals have a limited life and high frequency of replacement compared to other mechanical parts. The labor and downtime costs associated with replacing seals tend to be higher than the value of the seal itself.

Therefore, once a specific part or a plurality of specific parts of the mechanical equipment are repaired, it is generally said that the seals or wearing parts related to the position are all replaced at one time. In this way, the seal repair kit came into being.

DSH Seals' seal repair kit series products have been used by professional equipment manufacturers and exported to Europe, the United States, the Middle East and other markets. Good quality has been unanimously affirmed by customers.

Second, oil & gas seals (gold spring spring energized seal PTA)

Oil is an ancient biological remains, which is carried out in the lake, in the sea or on land, and is transformed by complex biological and chemical effects through the action of high temperature and high pressure.

Dispersed sedimentary organic matter or combustible organic minerals (oil, coal and oil shale), during the diagenesis and maturation process, the formation of natural gas based on hydrocarbon gas by microbial degradation and pyrolysis. Oil and natural gas often come together.

Third. Hydraulic & Pneumatic Seals (Rotary shaft glyd ring DNS)

The development history of hydraulic and pneumatic seals in China can be roughly divided into three stages. Namely: from the early 1950s to the early 1960s, it was the initial stage; from the 1960s to the 1970s, it was the stage of development of specialized production systems; from the 1980s to the 1990s, it was the stage of rapid development.

Coaxial seals: Coaxial seals represented by the step seals/glyd ring are mostly used in hydraulic cylinders. The pressure can reach 60MPa or higher and the speed is up to 15m/s; the use temperature is between -40 and 200 °C (determined by the corresponding elastomer material). Seal products produced by DSH Seals: It has been widely used in the hydraulic and pneumatic industries and has been exported to the international market. It has won the trust of customers.

Fourth, metallurgical industry seals (PTFE oil seal B type)

Hydraulic technology has greatly promoted the realization of the automated production process in the modern metallurgical industry. Different auxiliary equipment in the production process of steel smelting and continuous casting machines are inseparable from the function of the hydraulic system.

Compared with the traditional mechanical transmission, the hydraulic equipment has the advantages of easy assembly and low cost, and is beneficial to the economic benefit of the metallurgical enterprise, and is a more economical and reasonable choice. Hydraulic systems have been developed and used in a wide range of applications in the metallurgical industry, so hydraulic seals are playing an increasingly important role in the metallurgical industry.

DSH Seals has become a qualified supplier of daily equipment maintenance for a large steel group in China. We have reduced the frequency of equipment replacement seals and produced good economic benefits.

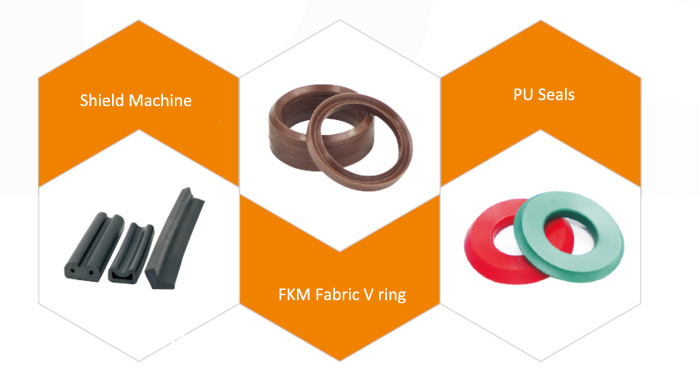

Five, engineering shield mechanical seals

The shield machine is a tunnel boring machine using a shield method. The construction method of the shield is to construct the tunnel "shield" (referred to as the supporting tube piece) while digging into the machine, which is different from the open construction method.

The internationally generalized shield machine can also be used for rock formations, but is distinguished from open (non-shield) tunnel excavators. In China, it is customary to use a tunnel boring machine for soft soil layers as a shield machine, which will be used as a TBN for rock formations.

According to the working principle, the shield machine is generally divided into a hand-drilled shield, a squeezed shield, a semi-mechanical shield, and a mechanical shield. The seal at the hinge of the shield machine is especially important. DSH Seals' engineering shield mechanical seal: widely used in high-speed rail and subway construction, and contributed.

Six. Coal mine mechanical seals

Coal mining machinery belongs to a large classification of machinery, mainly refers to mining machinery used in mining, mining, transportation, washing and other production processes. Coal mining machinery is different from other mining machinery due to its professional characteristics.

As a big country in coal production, the production of coal machinery plays an important role in China. The drum seals, mountain seals, bud seals and dust seals produced by DSH Seals are all important sealing components in coal mine hydraulic supports.

Seven, power equipment seals

Power equipment mainly includes two major categories of power generation equipment and power supply equipment. Power generation equipment is mainly power station boilers, steam turbines, gas turbines, water turbines, generators, transformers, etc. Power supply equipment is mainly transmission circuits, transformers, contactors and the like of various voltage levels. Mechanical seals are oil-sealing devices for rotating machinery, such as centrifugal pumps, centrifuges (seals), reactors, and compressors.

Since the drive shaft runs through the inside and outside of the device, there is a circumferential gap between the shaft and the device through which the medium in the device leaks outward. If the pressure inside the device is lower than atmospheric pressure, the air leaks into the device. Therefore, there must be a shaft seal that prevents leakage. There are many types of shaft seals.

Because mechanical seals have the advantages of less leakage and long life, the world's mechanical seals are the main shaft seals in these equipments. DSH Seals produces electric series high temperature seals: it has become a commonly used qualified equipment for equipment maintenance of a well-known power group in China. We have reduced the frequency of equipment replacement seals and have produced good economic benefits.

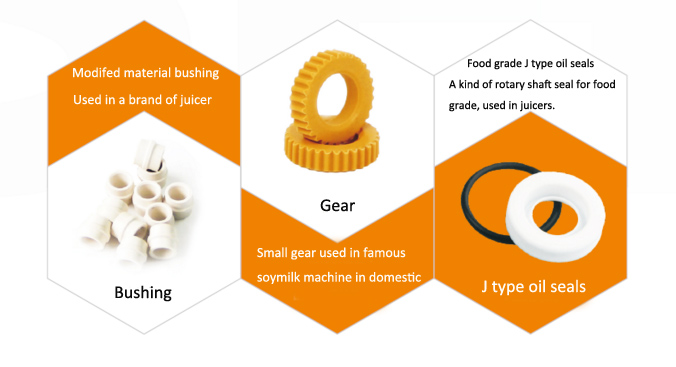

DSH Seals is a technology production enterprise integrating R&D, production and sales. It owns professional production plants and branches, and is mainly engaged in the research, manufacture and sales of seals in various industries. It has domestic self-owned brands such as DSH, DÑS , and AMT. Its products are exported to overseas markets such as Asia, Europe, the United States, and the Middle East and etc.