Product Series

News

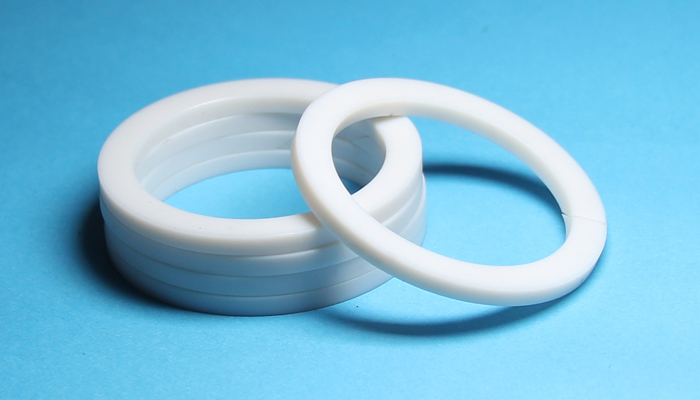

Application of PTFE Back up Ring

Update:2018-09-05

PTFE Back up ring is a new type seal products, is the breakthrough of domestic and abroad new technology in the sealing field. PTFE back up ring changed the traditional using way of static seals. It is the high-quality and useful seals. PTFE back up ring replaced PTFE seals and other materials seals due to its excellent performance, more and more popular in all types of industries and widely used.

PTFE back up ring can effectively prevent leakage of all types mechanical equipment, fuel tank end caps, cylinder end caps, gearbox end caps, various pipe flanges, installations, storage containers, towers, tanks, and especially non-metallic industrial production facilities, strengthen sealing effect.

It is an effective tool for industrial enterprises and related industries to solve the problem of “running, dripping and leaking” of gas and liquid media. PTFE back up ring can replace rubber gaskets, related products gaskets. It is a very novel and unique sealing material, which is made by a unique processing technology.

It can compensate and balance the errors caused by defects, machining, rigid deformation, installation misalignment, etc., balance the unevenness of the preload, and effectively solve the leakage problems of various facilities under complex conditions.