Product Series

News

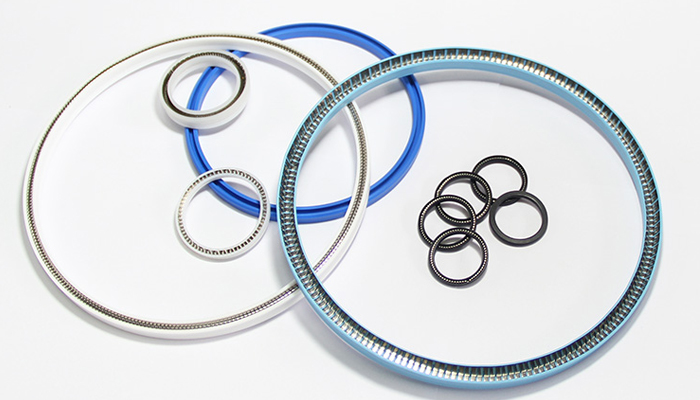

The main application and characteristics of spring energized seals

Update:2018-10-06

The spring energized seal is a high-performance seal with a special spring in the U-shaped PTFE seal. The appropriate spring force and system fluid pressure push the sealing lip (face) out and gently press the sealed metal surface, is designed to produce very good sealing properties.

The actuating effect of the spring overcomes the slight eccentricity of the metal mating surface and the wear of the sealing lip while maintaining the desired sealing effect.

The spring energized seals are the developed special products for high temperature corrosion, difficult lubrication and low friction applications, the combination of different PTFE filling materials, engineering plastics and corrosion resistant metal springs can fully meet the needs of an increasingly diverse and diverse industrial work environment. Typical applications are as follows:

1. Axial seals for loading and unloading arm rotary joints;

2. Seals for painting valve parts or painting systems;

3. Vacuum pump seals;

4. Beverage, water, beer filling equipment (such as filling valves) and seals for the food industry;

5. Automotive, aerospace industrial seals, such as power steering;

6. Sealing device for measuring equipment (low friction, long life);

7. Other process equipment or seals for pressure vessels.

Features of the spring energized seals:

1. The sealing performance of PTFE spring energized seal is not affected by insufficient lubrication when starting mechanical equipment;

2. PTFE spring energized seal reduces wear and friction resistance;

3. Through the combination of different sealing materials and different springs, it can display different sealing performance to meet various application requirements. It is made of special CNC processing machine, no mold cost, especially suitable for a small number of users;

4. Chemical corrosion resistance and heat resistance are superior to the commonly used rubber seals, stable dimension, sealing performance failure problems derived from volume expansion or contraction;

5. The structure of spring energized seal is exquisite and can be installed in the standard O-ring groove, greatly improve the sealing performance and use;

6. The spring energized seals can be filled with any anti-pollution material (such as silicone), but it is not suitable for radiation environment. Because PTFE material is very clean, it will not be polluted, the friction coefficient is very low, and it is very smooth even at very low speed. No sluggish effect, low starting friction resistance, and low starting performance even with long downtime or intermittent operation.