Product Series

News

Tearing, extrusion and reversal of Y ring

Update:2018-12-19

Y-ring is also one of the most widely used types of seals in the industry. DSH Seals share with you that when there is no Y-ring, the U-ring is also a place in the high-pressure environment. U-ring acts on the inside of the high-pressure lower lip with a high pressure.

At this time, there is a good self-sealing effect, but because the bottom is very thin and has a circular arc shape, the internal pressure creates a large tension there, so it is easy to tear there, especially the leather pad. At the same time, the bottom accommodates the deformation after tearing because of the remaining space.

This will make the damage rate of the leather filler high. In order to avoid the damage rate of the sealing ring, the bottom of the rubber U-ring is thickened at the time of design, thus evolving a "Y" letter-shaped sealing ring. Later, it was called "Y-ring " .

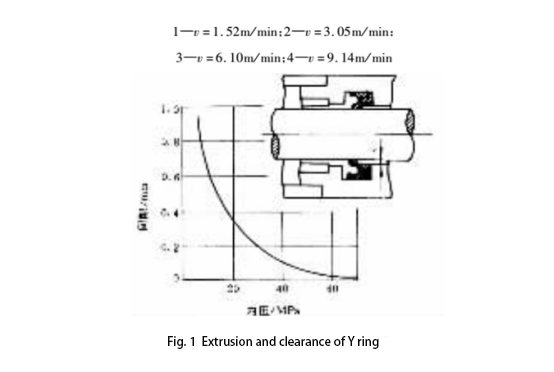

A thickened Y-ring at the bottom, although it can prevent tearing, when the internal pressure is high enough, the bottom will be "squeezed by rubber (rubber sealing material)" due to concentration. This is similar to the situation in O-rings. The relationship between internal pressure and clearance when extrusion occurs (Figure 1 shows the extrusion and clearance diagram of the Y-ring)

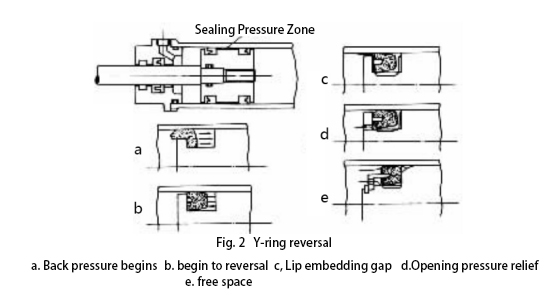

The "reverse" phenomenon of Y-ring occurs in the intermittent piston of the intermittent operation. At this time, since the gap between the two seal rings forms a small closed space, the pressure here reaches a large value during operation (the Y-ring reverse structure diagram is shown in Fig. 2).

When the working pressure is removed, the sealing pressure is pushed from the back to the other side (can be a structure in Fig. 2), when moving to the notch, because the gap is large, the sealing ring is Start “reverse” and the lip is embedded in the gap, causing damage to the seal.

In order to avoid such damage, a small hole (b structure in Fig. 2) can be opened at the bottom of the piston groove. In this way, when the internal pressure is removed, the Y-ring is moved, the sealing pressure is immediately connected to the in-cylinder pressure, the pressure is eliminated, the movement of the ring is stopped, and the reversal cannot occur. If positioned with a support ring, the effect will be better (e structure in Figure 2).