Product Series

News

A very hard PTFE O-type combination seal

Update:2019-01-15

A combination of "hard" seals for PTFE O-rings can also be used in specific applications. DSH Seals share with you that this seal consists of a hard seal section with a flexible cushion. The "hard" section can be metallic or some other low friction material (such as polytetrafluoroethylene). It is essentially a compression-type seal and the elasticity is given by a cushion seal. A possible advantage of this seal is that it acts as a bearing and seal, accommodates lateral clearance, and provides an automatic "centering" effect.

A specific example here is the combination of an O-ring seal and a rigid Teflon seal. The latter provides a low friction sealing surface, whether or not it is lubricated. The sealing ring can be an inner seal or an outer seal (the structure diagram of the inner seal and the outer seal of the O-shaped seal seal shown in Fig. 1), and the seal name produced by different seal manufacturers is also different (polytetrafluoroethylene) The shape of the vinyl seal is also different). The most famous in the UK is the (Angus) slip O-ring.

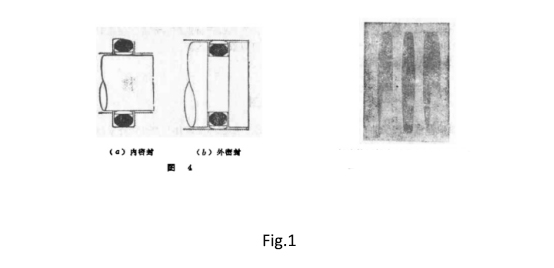

Compared with the performance of the traditional O-ring seal (Figure 2 shows the relationship between the friction and pressure of the typical seal ring in the O-type seal ring, Figure 3 shows The relationship between the friction and pressure of a typical seal of an O-type combination seal under lubrication conditions). Interestingly, although its sealing performance is excellent under moving conditions, the static friction is close to the 0-ring.

It is also worth noting that at very low pressures, the lip seal exhibits the lowest friction (Figure 3 shows the relationship between the friction and pressure of a typical seal of the O-combined seal in the lubricated state), However, in this case, as the pressure rises, the contact area of the lips increases, and the frictional force increases.