Product Series

News

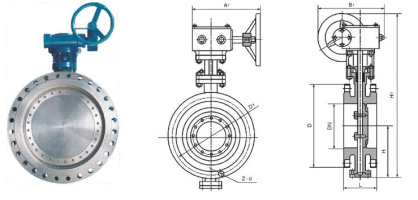

Sealing principle of hard seal butterfly valve

Update:2019-01-17

Whether it's design or choice, we need to understand how it works, so that we can be more aware of the need for improvement.

The hard-sealed butterfly valve is a valve that realizes the opening or closing of the pipe by the rotation of the circular butterfly plate (sealing member) with the valve shaft. It is mainly used as a shut-off valve, and can also be designed to have the functions of cutting and throttling adjustment. At present, the use of hard-sealed butterfly valves on low-pressure large and medium-diameter pipes is increasing.

The disc of the hard seal butterfly valve is mounted in the diameter direction of the pipe. In the cylindrical passage of the butterfly valve body, the disc-shaped disc rotates around the axis, and the rotation angle is between 0° and 90°. When rotated to 90°, the valve is fully open.

The hard sealing butterfly valve is simple in structure, small in size and light in weight, and consists of only a few parts. Moreover, it can be quickly opened and closed by only rotating 90°, and the operation is simple, and the electric valve has good fluid control characteristics.

When the butterfly valve is in the fully open position, the thickness of the disc is the only resistance when the medium flows through the valve body, so the pressure drop generated by the valve is small, so it has better flow control characteristics. The butterfly valve has two sealing types: a spring seal and a metal seal. Elastomeric sealing valve, the sealing ring can be mounted on the valve body or attached to the periphery of the disc.

If a butterfly valve is required for flow control, the main choice is the correct size and type of valve. The structural principle of the hard-seal butterfly valve is especially suitable for making large-diameter valves. Hard-sealed butterfly valves are widely used not only in general industries such as petroleum, gas, chemical, and water treatment, but also in cooling water systems for thermal power plants.