Product Series

News

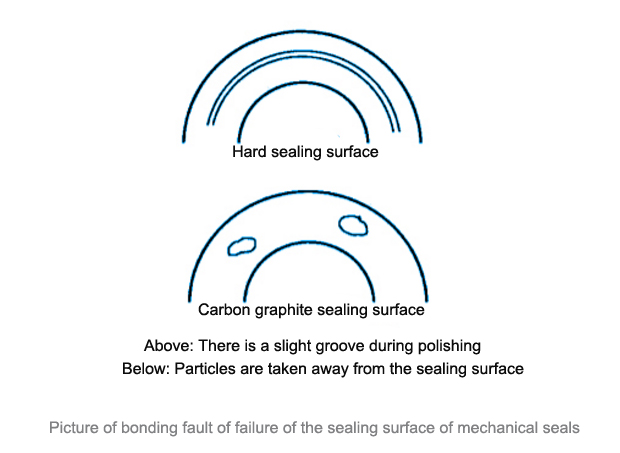

Sealing failure of sealing surface adhension on automotive seals

Update:2018-06-20

Automotive seals often exhibit leakage, wear, power consumption, overheating, smoke, vibration, etc malfunction. Taking the automotive seals for pumps as an example, a detailed explanation will be given of the various failure phenomena of the automotive seals, the causes of the production, and the consequences resulting from the application of the adopted standards for metabolism and use.

First, picture of the failure of the sealing surface adhesion of automotive seal

Second, the cause of the seal surface adhesion of the automotive seal failure:

Bonding of automotive seals is a phenomenon similar to flaws. One of the main reasons for bonding is that the pump or equipment uses different products for experimental operation, and the experimental liquid reacts with the working product in the diaphragm during operation; the other cause is caused by the surrounding environment, such as the Freon gas compressor. The liquid film in its shaft seal was contaminated with Freon gas. In standby, the oil deteriorates and the oil film will stick to the seal surface.

Third, Symptoms of seal adhesion on the fault of automobile seals and measures taken

Bonding failure of automotive seals Symptoms: Adhesion to the surface of the seal is similar to that of helium

Measures to deal with adhesion failures: For the first reason, the measures that can be taken are that the equipment with such failures should pay attention to using a suitable test fluid or run it with a neutral medium after the experiment.